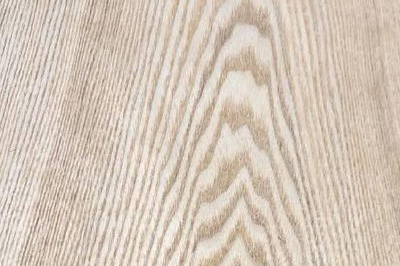

All our products are made of high-quality materials. Our staircase and railing projects are generally made of metal, glass, wood, etc.

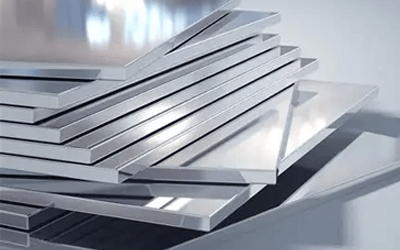

1. Metal

Commonly used metals include stainless steel, iron, aluminum, etc.

1.1 Stainless steel

Stainless steel is corrosion-resistant, easy to clean, beautiful and durable. We mainly use it in railings and railing connectors. Staircase projects are mainly used in stair handrails and columns. The main stainless steels we use are SS304 and SS316.

- SS 304: can be used indoors and outdoors far from the seaside (>10 km).

- SS 316: resistant to strong acids and alkalis, strong anti-corrosion effect, can be used at the seaside.

- SS 316L: a higher grade than 316, good quality, material shortage, expensive.

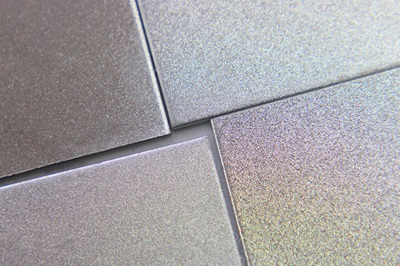

Surface Finishes Available

Stainless steel sheets and plates can be explored to give you an endless array of aesthetic potentials where each option of stainless steel finishes produces a unique feel. From smooth sophistication of brushed and mirror finishes to unique textures of sandblasted before vibrating with versatility that extends functionality while adding a touch of elegance to your applications.

Baking Paint

Mirror Finished

Baking Paint

Passivation

Electroplating

1.2 Steel

Steel is mainly used in the stair keel part. The steel materials we mainly use are: A3 steel, Q235. The surface treatment of steel is as follows:

Spraying: ordinary paint or powder

Effect: gloss, matte/sanding (matt)

Color: black, white, gray, silver, etc. (can be customized according to needs)

Hot Galvanizing:

The surface is silver after hot-dip galvanizing. Zinc particles or zinc slag will adhere to the surface after galvanizing. It is not smooth and flat enough. It can be lightly polished and trimmed before baking. The surface is rough after baking, which is suitable for sand surface paint (such as sand white, sand black, sand gray, etc.). Hot-dip galvanized products have strong anti-rust ability, but the paint adhesion is poor, and the surface paint is easy to fall off; it is suitable for outdoor products and can be used at the seaside.

fluorocarbon painting:

The processing technology and surface effect are the same as ordinary paint or powder, and the primer and topcoat can be directly baked after polishing. Fluorocarbon paint has a strong anti-rust function, and the effect is equivalent to: hot-dip galvanizing + baking paint. The paint surface has strong adhesion and the surface color is durable.

1.3 Aluminum

The hardness of aluminum is lower than that of iron and stainless steel, and it is usually used for railings and bathroom doors. Surface treatment of aluminum:

Electrophoresis: frosted white, imitation steel color (same effect as champagne gold)

Oxidation: silver white (common primary color of aluminum)

Spraying: process, color and effect are the same as Q235 steel surface

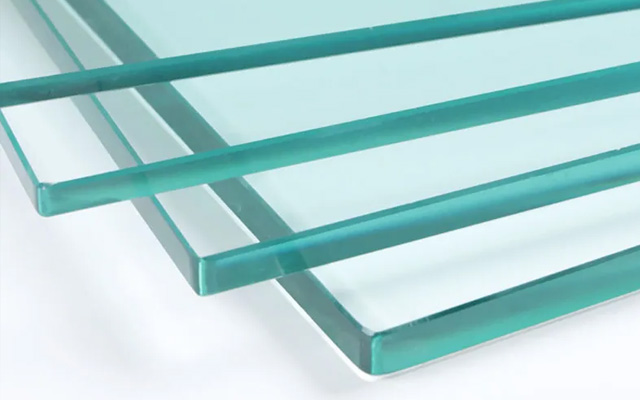

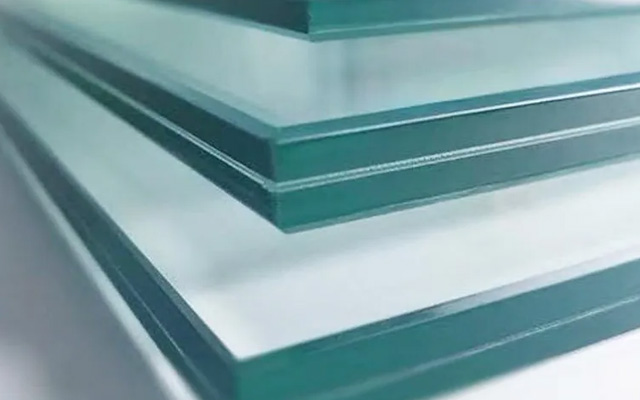

3. Glass

Glass is commonly used in railings, stair railings and treads. It is a combination of strength, safety and design. Tempered and laminated glass brings more than just durability. It has an inherent layer structure that creates an extra level of safety and security.

Tempered Glass

Tempered glass is stronger and safer and hence used for frameless railings. Using a peculiar way of heating and rapid cooling, i.e. at least ten times more than the usual glass. In case of a break, the tempered glass will fragment into dull, small chunks, not dangerous, therefore the glass is perfect for glazing the balconies which are meant to fulfill the decorative and safe function.

Laminated Tempered Glass

Laminated tempered glass is the association of some glass pieces which is bonded by the sandwiching of a transparent PVB layer. This procedure also increases the almost complete shatter resistance, save for glass fragments that do not fly everywhere out, because they are secured by the interlayer film. In addition, it enhances soundproofing and UV blocking, which has many balcony benefits.